1. Ibikoresho byo gushakisha

.Ibyuma byuzuza ibyuma bikoreshwa mugukata cyane harimo ifeza ya feza, aluminium base, titanium base cyangwa titanium zirconium base.

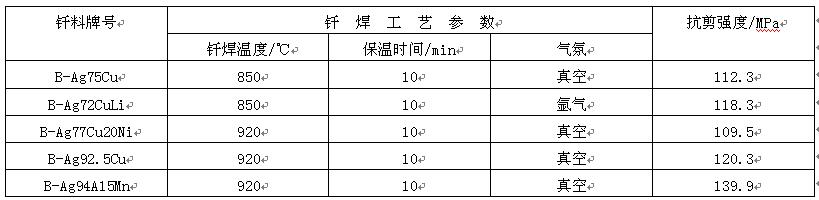

Ifeza ishingiye kumugurisha ikoreshwa cyane cyane mubice bifite ubushyuhe bwakazi buri munsi ya 540 ℃.Ihuriro ukoresheje kugurisha ifeza yuzuye rifite imbaraga nke, byoroshye gucika, hamwe no kurwanya ruswa no kurwanya okiside.Ubushyuhe bukabije bwa Ag Cu ugurisha buri munsi yifeza, ariko ubushuhe buragabanuka hamwe no kwiyongera kwa Cu.Ag Cu ugurisha irimo Li nkeya irashobora kunoza ubushuhe hamwe nurwego ruvanze hagati yugurisha nicyuma fatizo.AG Li ugurisha afite ibiranga gushonga hasi no kugabanuka gukomeye.Birakwiriye gusya titanium na titanium alloys mukirere gikingira.Ariko, gushakisha vacuum bizanduza itanura kubera Li ihinduka.Ag-5al- (0.5 ~ 1.0) Mn yuzuza ibyuma nicyuma cyuzuza icyuma cyoroshye cya titanium alloy ibice.Igice gifatanye gifite okiside nziza kandi irwanya ruswa.Imbaraga zogosha za titanium na titanium alloy ingingo zometseho icyuma cya feza zuzuza ibyuma bigaragara mumeza 12.

Imbonerahamwe 12 ibipimo byerekana uburyo hamwe nimbaraga za titanium na titanium

Ubushyuhe bukabije bwa aluminiyumu ugurisha ni buke, butazatera kubaho kwa titanium all Guhindura icyiciro bigabanya ibisabwa kugirango hatorwe ibikoresho nibikoresho byubaka.Imikoranire hagati yicyuma cyuzuza nicyuma fatizo ni gito, kandi gusesa no gukwirakwizwa ntabwo bigaragara, ariko plastike yicyuma cyuzuza ni cyiza, kandi biroroshye kuzinga ibyuma byuzuza nicyuma fatizo hamwe, nuko rero bikwiranye cyane no gushakisha titanium alloy radiator, imiterere yubuki nuburyo bwa laminate.

Titanium ishingiye cyangwa titanium zirconium ishingiye kuri flux muri rusange irimo Cu, Ni nibindi bintu, bishobora gukwirakwira vuba muri matrix hanyuma bigakorwa na titanium mugihe cyo gushakisha, bikaviramo kwangirika kwa matrix no gushiraho ibice byoroshye.Kubwibyo, ubushyuhe bwo gukonjesha no gufata umwanya bigomba kugenzurwa cyane mugihe cyo gushakisha, kandi ntibigomba gukoreshwa mugukata ibyubatswe binini cyane bishoboka.B-ti48zr48be numugurisha Ti Zr usanzwe.Ifite amazi meza kuri titanium, kandi icyuma cyibanze ntigifite imikurire yintete mugihe cyo kurisha.

.

.Isuku ryinshi argon izakoreshwa mugukingirwa gukingirwa, kandi ikime kigomba kuba -54 ℃ cyangwa munsi.Amazi adasanzwe arimo fluoride na chloride yicyuma Na, K na Li bigomba gukoreshwa mugukoresha umuriro.

2. Gukoresha tekinoroji

Mbere yo gushakisha, hejuru igomba gusukurwa neza, kugabanuka no gukuramo firime ya okiside.Filime yibyibushye igomba gukurwaho hakoreshejwe uburyo bwa mashini, uburyo bwo guturika umucanga cyangwa uburyo bwo kwiyuhagira umunyu.Filime yoroheje ya okiside irashobora gukurwaho mubisubizo birimo 20% ~ 40% acide nitric na 2% hydrofluoric.

Ti, Zr hamwe nudusimba twabo ntibyemewe guhuza ubuso hamwe numwuka mugihe cyo gushyushya.Brazing irashobora gukorwa mukurinda vacuum cyangwa gaze ya inert.Gukoresha inshuro nyinshi induction gushyushya cyangwa gushyushya mukurinda birashobora gukoreshwa.Gushyushya induction nuburyo bwiza kubice bito bihuje ibice, mugihe gushakisha mu itanura nibyiza cyane kubintu binini kandi bigoye.

Ni Cr, W, Mo, Ta nibindi bikoresho bizatoranywa nkibikoresho byo gushyushya Ti, Zr hamwe nuruvange rwabo.Ibikoresho bifite grafite igaragara nkibikoresho byo gushyushya ntibishobora gukoreshwa kugirango wirinde kwanduza karubone.Ibikoresho byo gusya bigomba kuba bikozwe mubikoresho bifite imbaraga zubushyuhe bwo hejuru, bisa na coefficente yo kwagura ubushyuhe bwa Ti cyangwa Zr, hamwe nubushake buke hamwe nicyuma fatizo.

Igihe cyo kohereza: Jun-13-2022