Gukata ibyuma bitagira umwanda

1. Brazeability

Ikibazo cyibanze mugukata ibyuma bidafite ingese nuko firime ya oxyde hejuru igira ingaruka zikomeye kubushuhe no gukwirakwiza kwabagurisha.Ibyuma bitandukanye bidafite umwanda birimo umubare utari muto wa Cr, kandi bimwe birimo Ni, Ti, Mn, Mo, Nb nibindi bintu, bishobora gukora oxyde zitandukanye cyangwa ndetse na oxyde ikomatanya hejuru.Muri byo, oxyde Cr2O3 na TiO2 ya Cr na Ti irahagaze neza kandi kuyikuramo biragoye.Iyo ukonje mu kirere, flux ikora igomba gukoreshwa kugirango ikureho;Iyo ushakisha mu kirere gikingira, firime ya oxyde irashobora kugabanuka gusa mu kirere cyiza cyane gifite ikime gito n'ubushyuhe buhagije;Muri vacuum brazing, birakenewe kugira vacuum ihagije nubushyuhe buhagije kugirango ugere ku ngaruka nziza.

Ikindi kibazo cyo gukata ibyuma bidafite ingese ni uko ubushyuhe bwo gushyuha bugira ingaruka zikomeye kumiterere yicyuma fatizo.Ubushyuhe bwo gushyushya ubushyuhe bwa austenitis butagira ibyuma ntibushobora kuba hejuru ya 1150 ℃, bitabaye ibyo ingano zizakura cyane;Niba ibyuma bya austenitike bidafite ibyuma bidafite Ti cyangwa Nb kandi bifite karubone nyinshi, kurigata mubushyuhe bwo gukangurira (500 ~ 850 ℃) nabyo biririndwa.Kugirango wirinde kwangirika kwangirika kugabanuka kubera imvura ya karubide ya chromium.Guhitamo ubushyuhe bwa brazing kuri martensitike idafite ibyuma birakomeye.Imwe muriyo ni uguhuza ubushyuhe bwa brazing hamwe nubushyuhe bwo kuzimya, kugirango uhuze inzira yo gushakisha hamwe nuburyo bwo kuvura ubushyuhe;Ikindi nuko ubushyuhe bwa brazing bugomba kuba munsi yubushyuhe bwubushyuhe kugirango wirinde icyuma fatizo koroha mugihe cyo gushakisha.Ihame ryo gutoranya ubushyuhe bwimyororokere yimvura ikomera ibyuma bidafite ingese ni kimwe nicyuma cya martensitike idafite ibyuma, ni ukuvuga ko ubushyuhe bwa brazing bugomba guhuza na sisitemu yo kuvura ubushyuhe kugirango ibone ibikoresho byiza bya mashini.

Usibye ibibazo bibiri byingenzi byavuzwe haruguru, harikibazo cyo gucika intege mugihe ucyuye ibyuma bitagira umuyonga wa austenitike, cyane cyane iyo ukoresheje icyuma cyuzuza umuringa.Kugirango wirinde gucika intege, urupapuro rwakazi rugomba koroherwa no gufatanwa mbere yo gushiramo, kandi igihangano kizashyuha kimwe mugihe cyo gushakisha.

2. Ibikoresho byo gushakisha

. icyuma cyuzuza ibyuma nicyuma cyagaciro brazing kuzuza ibyuma.

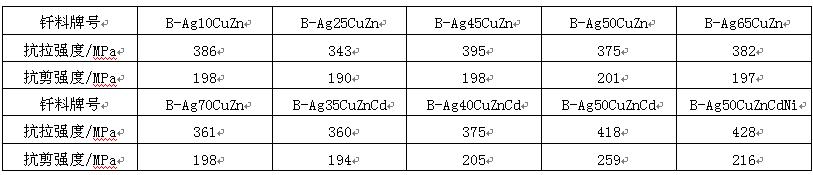

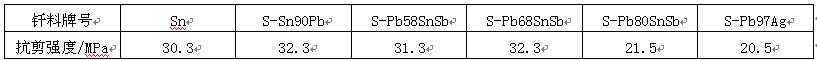

Amabati yo kugurisha amabati akoreshwa cyane cyane mu kugurisha ibyuma, kandi birakwiriye kugira amabati menshi.Iyo amabati ari hejuru yuwagurishije, niko arushaho guhindagurika kwicyuma.Imbaraga zogosha za 1Cr18Ni9Ti ibyuma bitagira umuyonga bifatanye hamwe nabagurisha amabati menshi asanzwe aboneka kurutonde rwa Imbonerahamwe 3. Bitewe nimbaraga nke zingingo, zikoreshwa gusa mugukata ibice bifite ubushobozi buke bwo gutwara.

Imbonerahamwe 3 yogosha imbaraga za 1Cr18Ni9Ti ibyuma bidafite ingese bifatanye hamwe na tin gurş kugurisha

Ifeza ishingiye ku kuzuza ibyuma ni byo bikoreshwa cyane mu kuzuza ibyuma bidafite ingese.Muri byo, feza y'umuringa wa zinc na silver y'umuringa zinc cadmium yuzuza ibyuma bikoreshwa cyane kubera ko ubushyuhe bwa brazing butagira ingaruka nke kumiterere yicyuma fatizo.Imbaraga za ICr18Ni9Ti ibyuma bitagira umuyonga bifatanye hamwe n’abacuruzi benshi basanzwe ba feza bishyirwa ku mbonerahamwe ya 4. Ihuza ibyuma bitagira ingese bifatanye n’abacuruzi bashingiye ku ifeza ntibikoreshwa cyane mu bitangazamakuru byangirika cyane, kandi ubushyuhe bw’akazi bw’ingingo muri rusange ntiburenga 300 ℃ .Mugihe cyo gutwika ibyuma bidafite ingese idafite nikel, kugirango hirindwe kwangirika kwingingo zometse ahantu h’ubushuhe, hazakoreshwa ibyuma byuzuza hamwe na nikel nyinshi, nka b-ag50cuzncdni.Mugihe cyo gukata martensitike idafite ibyuma, kugirango hirindwe koroshya ibyuma byibanze, hazakoreshwa ibyuma byuzuza hamwe nubushyuhe butarenze 650 ℃, nka b-ag40cuzncd.Iyo ucyuye ibyuma bitagira umwanda mukirere kirinda, kugirango ukureho firime ya oxyde hejuru, lithium irimo flux flux irashobora gukoreshwa, nka b-ag92culi na b-ag72culi.Iyo usya ibyuma bitagira umwanda muri vacuum, kugirango ukore icyuma cyuzuza kigifite amazi meza mugihe kitarimo ibintu nka Zn na CD byoroshye guhumeka, ibyuma byuzuza ifeza birimo ibintu nka Mn, Ni na RD birashobora kuba Byahiswemo.

Imbonerahamwe 4 imbaraga za ICr18Ni9Ti ibyuma bidafite ingese bifatanye hamwe na feza ishingiye ku cyuma

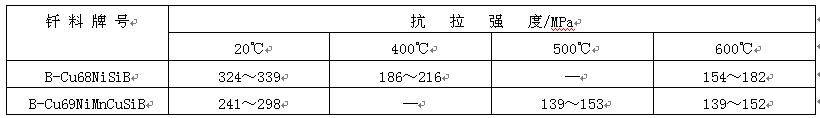

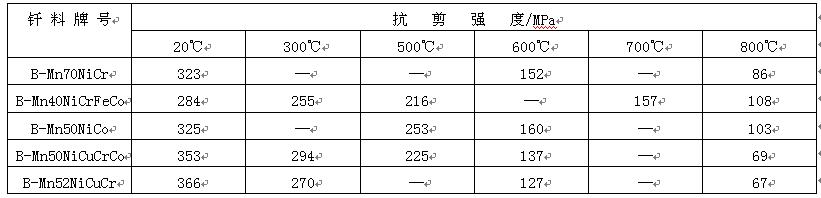

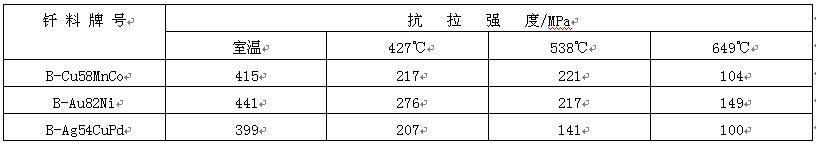

Umuringa ushingiye kumuringa wuzuza ibyuma bikoreshwa mugukata ibyuma bitandukanye cyane cyane ni umuringa usukuye, nikel y'umuringa na manganese cobalt brazing kuzuza ibyuma.Icyuma cyuzuye umuringa wuzuza icyuma gikoreshwa cyane mugukata munsi yo kurinda gaze cyangwa vacuum.Ubushyuhe bwo gukora bwibyuma bidafite ingese ntibirenga 400 but, ariko urugingo rufite imbaraga zo kurwanya okiside.Umuringa nikel brazing wuzuza ibyuma bikoreshwa cyane cyane mugukoresha flame no gushakisha induction.Imbaraga zumuringa 1Cr18Ni9Ti zifatanije nicyuma cyerekanwe kumeza ya 5. Birashobora kugaragara ko urugingo rufite imbaraga nkicyuma fatizo, kandi ubushyuhe bwakazi buri hejuru.Cu Mn co brazing yuzuza ibyuma bikoreshwa cyane mugukata ibyuma bya martensitike bitagira umwanda mukirere kirinda.Imbaraga hamwe nubushyuhe bwo gukora biragereranywa nibisizwe hamwe na zahabu yuzuye ibyuma.Kurugero, 1Cr13 ibyuma bitagira umuyonga bifatanyirijwe hamwe na b-cu58mnco ugurisha bifite imikorere imwe nki cyuma kimwe kidafite ingese hamwe na b-au82ni ugurisha (reba Imbonerahamwe 6), ariko igiciro cyumusaruro kiragabanuka cyane.

Imbonerahamwe 5 yogosha imbaraga za 1Cr18Ni9Ti ibyuma bidafite ingese bifatanye hamwe nubushyuhe bwo hejuru bwumuringa wuzuza ibyuma

Imbonerahamwe 6 yogosha imbaraga za 1Cr13 ibyuma bidafite ingese

Manganese ishingiye kuri brazing yuzuza ibyuma bikoreshwa cyane cyane mugukingira gaze ikingiwe, kandi isuku ya gaze isabwa kuba hejuru.Kugirango wirinde gukura kw'ingano z'icyuma fatizo, hagomba gutoranywa icyuma cyuzuza icyuma cyuzuye hamwe n'ubushyuhe buri munsi ya 1150 ℃.Ingaruka zishimishije zirashobora kuboneka kubintu byuma bidafite ingese hamwe na manganese ugurisha, nkuko bigaragara mu mbonerahamwe ya 7. Ubushyuhe bwakazi bwurugingo bushobora kugera kuri 600 ℃.

Imbonerahamwe 7 yogosha imbaraga za lcr18ni9fi ibyuma bidafite ibyuma bifatanye hamwe na manganese ishingiye kubyuma

Iyo ibyuma bitagira umuyonga bisizwe hamwe na nikel base yuzuza ibyuma, urugingo rufite imikorere myiza yubushyuhe bwo hejuru.Icyuma cyuzuza gikoreshwa muri gaze ikingira gaze cyangwa gushakisha vacuum.Kugirango utsinde ikibazo cyuko ibintu byinshi bivunaguye bikorerwa mubice bifatanye mugihe cyo guhuriza hamwe, bigabanya cyane imbaraga na plastike yingingo, icyuho kigomba kugabanywa kugirango harebwe ko ibintu byoroshye gukora icyiciro cyoroshye muri umugurisha yakwirakwijwe rwose mubyuma shingiro.Kugirango wirinde ko habaho gukura kwicyuma cyibanze bitewe nigihe kinini cyo gufata ubushyuhe bukabije, ingamba zo gufata igihe gito no kuvura ikwirakwizwa ryubushyuhe buke (ugereranije nubushyuhe bwa brazing) nyuma yo gusudira.

Ibyuma byiza bya brazing byuzuza ibyuma bikoreshwa mugukata ibyuma bitagira umwanda cyane cyane birimo ibyuma byuzuza zahabu na palladium birimo ibyuma byuzuza, muribyo bisanzwe ni b-au82ni, b-ag54cupd na b-au82ni, bifite ubushuhe bwiza.Icyuma gitsindagiye icyuma gifite imbaraga zo hejuru yubushyuhe hamwe no kurwanya okiside, kandi ubushyuhe ntarengwa bwo gukora burashobora kugera kuri 800 ℃.B-ag54cupd ifite ibintu bisa na b-au82ni kandi igiciro cyayo ni gito, bityo ikunda gusimbuza b-au82ni.

.Iyo ibyuma bitagira umwanda bisizwe hamwe nugurisha amabati, flux ikwiye ni acide ya fosifori yumuti cyangwa umuti wa zinc oxyde hydrochloric.Igihe cyibikorwa bya acide ya fosifori yo mumazi ni mugufi, bityo rero uburyo bwo gushakisha ubushyuhe bwihuse bugomba gukoreshwa.Fb102, fb103 cyangwa fb104 fluxes irashobora gukoreshwa mugukata ibyuma bitagira umwanda hamwe nibyuma byuzuza feza.Iyo usya ibyuma bidafite ingese hamwe nicyuma gikozwe mu muringa, fb105 flux ikoreshwa kubera ubushyuhe bwinshi.

Iyo usya ibyuma bitagira umwanda mu itanura, ikirere cya vacuum cyangwa ikirere gikingira nka hydrogen, argon na ammonia yangirika.Mugihe cyo gushakisha icyuho, umuvuduko wa vacuum ugomba kuba munsi ya 10-2Pa.Iyo ukonje mu kirere gikingira, aho ikime cya gaze ntigishobora kuba hejuru ya -40 ℃ Niba isuku ya gaze idahagije cyangwa ubushyuhe bwa brazing ntabwo buri hejuru, umubare muto wa gaze ya gazi, nka boron trifluoride, irashobora Ongeraho mu kirere.

2. Gukoresha tekinoroji

Ibyuma bitagira umwanda bigomba guhanagurwa cyane mbere yo gushakisha kugirango ukureho amavuta yose hamwe namavuta.Nibyiza gucana ako kanya nyuma yo gukora isuku.

Ibyuma bidafite ibyuma birashobora gukoresha flame, induction hamwe nitanura uburyo bwo gushyushya ibintu.Itanura ryo gutwika mu itanura rigomba kugira uburyo bwiza bwo kugenzura ubushyuhe (gutandukana kwubushyuhe bwa brazing bisabwa kuba ± 6 ℃) kandi birashobora gukonjeshwa vuba.Iyo hydrogène ikoreshwa nka gaze ikingira gukonjesha, ibisabwa kuri hydrogène biterwa nubushyuhe bwo gutwika hamwe nibigize icyuma fatizo, ni ukuvuga, uko ubushyuhe bwo hasi bugenda bwiyongera, niko icyuma fatizo kirimo stabilisateur, kandi ikime kikamanuka. ingingo ya hydrogen irakenewe.Kurugero, kuri martensitike idafite ibyuma nka 1Cr13 na cr17ni2t, mugihe ushonje kuri 1000 ℃, ikime cya hydrogène gisabwa kuba munsi ya -40 ℃;Kuri 18-8 chromium nikel idafite ibyuma idafite stabilisateur, aho ikime cya hydrogène kizaba kiri munsi ya 25 ℃ mugihe cyo gushakisha kuri 1150 ℃;Nyamara, kuri 1Cr18Ni9Ti ibyuma bitagira umwanda birimo stabilisateur ya titanium, ikime cya hydrogène kigomba kuba munsi ya -40 ℃ mugihe cyogeye kuri 1150 ℃.Iyo ushakisha kurinda argon, ubuziranenge bwa argon burasabwa kuba hejuru.Niba umuringa cyangwa nikel bishyizwe hejuru yicyuma kitagira umwanda, ibisabwa kugirango isuku ya gaze ikingire irashobora kugabanuka.Kugirango hamenyekane gukuraho firime ya oxyde hejuru yicyuma kitagira umwanda, gazi ya BF3 irashobora kandi kongerwamo, kandi na lithium cyangwa boron irimo kugurisha ibicuruzwa.Iyo vacuum ifata ibyuma bidafite ingese, ibisabwa kugirango impamyabumenyi ya vacuum iterwa n'ubushyuhe bukabije.Hamwe n'ubwiyongere bw'ubushyuhe bukabije, icyuho gisabwa kirashobora kugabanuka.

Inzira nyamukuru yicyuma kitagira umuyonga nyuma yo gusya ni ugusukura flux zisigaye hamwe na inhibitor itemba, kandi ugakora post brazing ubushyuhe nibiba ngombwa.Ukurikije flux nuburyo bwa brazing bwakoreshejwe, flux isigaye irashobora gukaraba namazi, gusukurwa mumashini cyangwa gusukurwa mumiti.Niba abrasive ikoreshwa mugusukura flux isigaye cyangwa firime ya okiside ahantu hashyushye hafi yumutwe, umucanga cyangwa ibindi bice bitari byiza byuma bizakoreshwa.Ibice bikozwe mu byuma bya martensitike bitagira umuyaga hamwe n’imvura igwa ibyuma bitagira umwanda bikenera kuvurwa ubushyuhe ukurikije ibisabwa byihariye byibikoresho nyuma yo kubitsa.Ibyuma bitagira umuyonga bisizwe hamwe na Ni Cr B na Ni Cr Si byuzuza ibyuma akenshi bivurwa no gukwirakwiza ubushyuhe nyuma yo gukata kugirango bigabanye ibisabwa kugirango habeho icyuho no kunoza microstructure hamwe nimiterere yingingo.

Igihe cyo kohereza: Jun-13-2022