Brazing of Superalloys

.Bafite imiterere yubukanishi, kurwanya okiside no kurwanya ruswa mubushyuhe bwinshi.Nickel base alloy niyo ikoreshwa cyane mubikorwa bifatika.

Superalloy irimo Cr nyinshi, na Cr2O3 oxyde ya firime bigoye kuyikuramo iba hejuru mugihe cyo gushyushya.Nickel base superalloys irimo Al na Ti, byoroshye okiside iyo ishyushye.Kubwibyo, gukumira cyangwa kugabanya okiside ya superalloys mugihe cyo gushyushya no gukuraho firime ya oxyde nikibazo cyambere mugihe cyo gushakisha.Nka borax cyangwa acide ya boric muri flux irashobora gutera kwangirika kwicyuma cyibanze ku bushyuhe bukabije, boron yaguye nyuma yimyitwarire ishobora kwinjira mubyuma fatizo, bikaviramo kwinjirira hagati yisi.Kubijyanye na nikel fatizo ivanze nibintu byinshi bya Al na Ti, impamyabumenyi ya vacuum mumiterere ishyushye ntishobora kuba munsi ya 10-2 ~ 10-3pa mugihe cyo gushakisha kugirango wirinde okiside hejuru yubutaka mugihe cyo gushyushya.

Kugira ngo igisubizo gikomezwe kandi imvura igwe ikomeze nikel fatizo, ubushyuhe bwo gukonjesha bugomba kuba buhuye nubushyuhe bwo kuvura ibisubizo kugirango harebwe burundu ibintu bivanze.Ubushyuhe bwo gukonjesha buri hasi cyane, kandi ibintu bivanze ntibishobora gushonga burundu;Niba ubushyuhe bwa brazing buri hejuru cyane, ingano yibanze yicyuma izakura, kandi ibintu ntibizagarurwa na nyuma yo kuvura ubushyuhe.Ubushyuhe bukomeye bwibisubizo byibanze byibanze ni byinshi, mubisanzwe ntabwo bizahindura ibintu bifatika bitewe nubushyuhe bukabije.

Nikel base superalloys, cyane cyane imvura ikomeza amavuta, ifite impungenge zo gucika intege.Mbere yo gushakisha, imihangayiko ikorwa murigikorwa igomba kuvaho burundu, kandi ubushyuhe bwumuriro bugomba kugabanuka mugihe cyo gushakisha.

.Iyo ubushyuhe bwakazi bwibihuru butari hejuru, ibikoresho bishingiye kuri feza birashobora gukoreshwa.Hariho ubwoko bwinshi bwa feza bushingiye kubagurisha.Kugirango ugabanye imihangayiko yimbere mugihe cyo gushyushya umuriro, nibyiza guhitamo uwagurishije hamwe nubushyuhe buke bwo gushonga.Fb101 flux irashobora gukoreshwa mugukata hamwe na silver base yuzuza ibyuma.Fb102 flux ikoreshwa mugukonjesha imvura ikomeza superalloy hamwe nibirimo aluminiyumu nyinshi, kandi 10% ~ 20% sodium silike cyangwa aluminium flux (nka fb201) hiyongeraho.Iyo ubushyuhe bwa brazing burenze 900 ℃, fb105 flux igomba gutoranywa.

Iyo ushakisha mu cyuho cyangwa ikirere kirinda, umuringa usukuye urashobora gukoreshwa nkicyuma cyuzuza.Ubushyuhe bwo gukonjesha ni 1100 ~ 1150 ℃, kandi ingingo ntishobora kubyara ibibazo, ariko ubushyuhe bwakazi ntibushobora kurenga 400 ℃.

Nickel base brazing yuzuza icyuma nikintu gikunze gukoreshwa cyane cyuzuza ibyuma muri Superalloys kubera imikorere yubushyuhe bwo hejuru kandi nta guhagarika umutima mugihe cyo gushakisha.Ibintu nyamukuru bivangwa mubigurisha nikel base ni Cr, Si, B, kandi umubare muto wabagurisha urimo Fe, W, nibindi ugereranije na ni-cr-si-b, b-ni68crwb brazing yuzuza ibyuma bishobora kugabanya gucengera hagati yimiterere yabantu ya B mu cyuma fatizo no kongera ubushyuhe bwo gushonga intera.Nicyuma cyuzuza icyuma cyo gushakisha ubushyuhe bwo hejuru bwo gukora hamwe na turbine.Nyamara, umuvuduko wumugurisha W urimo uwagurishijwe uba mubi kandi icyuho gihuriweho kiragoye kugenzura.

Gukwirakwiza gukwirakwiza ibyuma byuzuza ibyuma ntabwo birimo Si element kandi bifite imbaraga nziza zo kurwanya okiside hamwe no kurwanya ibirunga.Ubushyuhe bwa brazing burashobora gutoranywa kuva 1150 ℃ kugeza 1218 ℃ ukurikije ubwoko bwabagurisha.Nyuma yo gushakisha, gufatanyiriza hamwe hamwe nibintu bimwe nicyuma fatizo urashobora kuboneka nyuma yo kuvura 1066 ℃.

.Mbere yo gushakisha, ubuso bugomba kwangirika kandi okiside ikurwaho na sandpaper polishing, kumva ibiziga byangiza, acetone scrubbing hamwe nogusukura imiti.Mugihe uhitamo ibipimo byo gushakisha, twakagombye kumenya ko ubushyuhe bwo gushyuha butagomba kuba hejuru cyane kandi igihe cyo gukata kigomba kuba gito kugirango wirinde imiti ikomeye hagati yimyunyu nicyuma fatizo.Kugirango wirinde icyuma fatizo guturika, ibice bitunganijwe bikonje bigomba kugabanuka mbere yo gusudira, kandi gushyushya gusudira bigomba kuba bimwe bishoboka.Ku mvura ikomeza superalloys, ibice bigomba kubanza kuvurwa neza, hanyuma bigashyirwa ku bushyuhe buri hejuru gato ugereranije no kuvura gusaza, hanyuma bikavurwa gusaza.

1) Gucana mu kirere gikingira itanura ryaka mu itanura ryikirere risaba isuku ryinshi rya gaze ikingira.Kuri superalloys hamwe na w (AL) na w (TI) munsi ya 0.5%, aho ikime kigomba kuba munsi ya -54 ℃ mugihe hakoreshejwe hydrogen cyangwa argon.Iyo ibikubiye muri Al na Ti byiyongereye, ubuso bwa alloy buracyafite okiside iyo bishyushye.Hagomba gufatwa ingamba zikurikira;Ongeramo umubare muto wa flux (nka fb105) hanyuma ukureho firime ya oxyde hamwe na flux;0.025 ~ 0.038mm igipfundikizo kibisi gishyizwe hejuru yibice;Shira umugurisha hejuru yibikoresho bigomba gutondekwa mbere;Ongeramo gazi nkeya ya gazi, nka boron trifluoride.

2) Vacuum brazing vacuum brazing ikoreshwa cyane kugirango ibone ingaruka nziza zo kurinda hamwe nubwiza bwa brazing.Reba imbonerahamwe ya 15 kumiterere yubukorikori busanzwe bwa nikel base superalloy.Kuri superalloys hamwe na w (AL) na w (TI) munsi ya 4%, nibyiza guhitamo amashanyarazi ya nikel 0.01 ~ 0.015mm nikel hejuru, nubwo guhanagura kugurisha bishobora gukemurwa nta kwitegura bidasanzwe.Iyo w (AL) na w (TI) birenze 4%, ubunini bwa nikel bugomba kuba 0.020.03mm.Gupfundikanya cyane nta ngaruka zo gukingira, kandi gutwikira cyane bizagabanya imbaraga zingingo.Ibice byo gusudira birashobora kandi gushyirwa mubisanduku byo gushakisha vacuum.Agasanduku kagomba kuzuzwa na getter.Kurugero, Zr ikurura gaze mubushyuhe bwo hejuru, ishobora gukora icyuho cyaho mumasanduku, bityo ikarinda okiside yubuso bwa alloy.

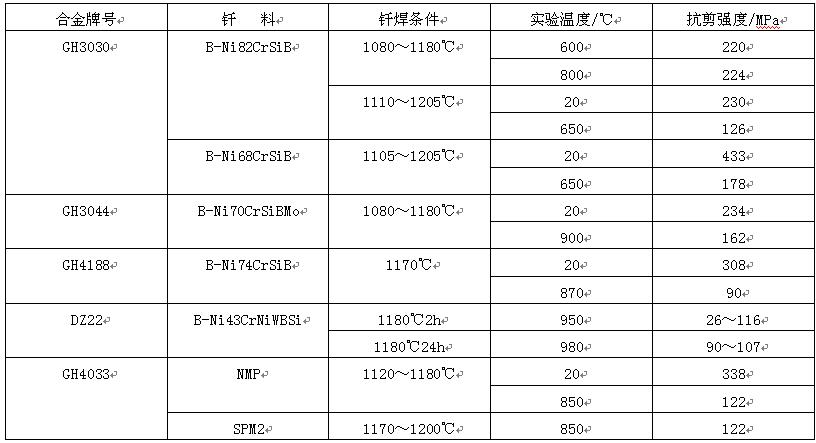

Imbonerahamwe 15 imiterere yubukorikori bwa Vacuum Brazed Guhuza bisanzwe nikel base superalloys

Microstructure and strength of brazed brained of Superalloy change with the brazing gaping, hamwe no gukwirakwiza diffuzion nyuma yo gukata bizarushaho kongera agaciro ntarengwa kemewe kumyanya ihuriweho.Dufashe urugero rwa Inconel nk'urugero, ikinyuranyo kinini cya Inconel ifatanye hamwe na b-ni82crsib irashobora kugera kuri 90um nyuma yo kuvurwa kuri 1000 ℃ kuri 1H;Nyamara, kubice byahujwe na b-ni71crsib, ikinyuranyo ntarengwa ni 50um nyuma yo kuvurwa kuri 1000 ℃ kuri 1H.

3) Amazi yinzibacyuho yigihe gito ihuza ibice byamazi byimyanya ikoresha interineti ihuza (hafi 2,5 ~ 100um yuburebure) aho gushonga biri munsi yicyuma fatizo nkicyuma cyuzuza.Munsi yumuvuduko muto (0 ~ 0.007mpa) hamwe nubushyuhe bukwiye (1100 ~ 1250 ℃), ibikoresho bya interlayer byabanje gushonga no kubumba ibyuma shingiro.Bitewe no gukwirakwizwa byihuse kwibintu, gukomera kwa isothermal bibaho kubihimba kugirango bibe bihuriweho.Ubu buryo bugabanya cyane ibisabwa bijyanye nuburinganire bwibanze kandi bigabanya umuvuduko wo gusudira.Ibipimo nyamukuru byamazi yigihe gito ihuza ni igitutu, ubushyuhe, gufata umwanya hamwe nibigize interlayer.Koresha igitutu gito kugirango ugumane ubuso bwo gusudira muburyo bwiza.Ubushyuhe n'ubushyuhe bigira ingaruka zikomeye kumikorere yingingo.Niba ingingo isabwa gukomera nkicyuma fatizo kandi ntigire ingaruka kumikorere yicyuma fatizo, ibipimo byo guhuza ibipimo byubushyuhe bwo hejuru (nka ≥ 1150 ℃) nigihe kirekire (nka 8 ~ 24h) bizaba byemewe;Niba ireme ryihuza ryibice bigabanutse cyangwa icyuma cyibanze ntigishobora kwihanganira ubushyuhe bwo hejuru, ubushyuhe bwo hasi (1100 ~ 1150 ℃) nigihe gito (1 ~ 8h) kizakoreshwa.Urwego ruciriritse rugomba gufata ibyuma fatizo bihujwe nkibigize shingiro, hanyuma ukongeramo ibintu bitandukanye byo gukonjesha, nka B, Si, Mn, Nb, nibindi. Urugero, ibigize Udimet alloy ni ni-15cr-18.5co-4.3 al-3.3ti-5mo, hamwe nibice bigize urwego rwagateganyo rwo guhuza ibyiciro byigihe gito ni b-ni62.5cr15co15mo5b2.5.Ibi bintu byose birashobora kugabanya ubushyuhe bwo gushonga bwa Ni Cr cyangwa Ni Cr Co alloys kugeza hasi, ariko ingaruka za B nizo zigaragara cyane.Mubyongeyeho, igipimo kinini cyo gukwirakwizwa kwa B kirashobora guhuza byihuse guhuza interlayer hamwe nicyuma fatizo.

Igihe cyo kohereza: Jun-13-2022