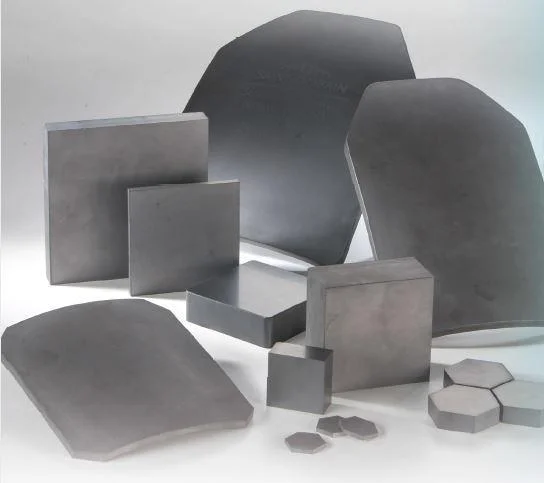

Ceramics ya silicon karbide ifite imbaraga zubushyuhe bwinshi, irwanya ubushyuhe bwinshi bwa okiside, irwanya kwambara neza, ituze ryiza ryumuriro, coefficente ntoya yo kwagura ubushyuhe, ubushyuhe bwinshi bwumuriro, ubukana bwinshi, kurwanya ubushyuhe, kurwanya ruswa yangiza nibindi bintu byiza cyane. Yakoreshejwe cyane mu binyabiziga, gukoresha imashini, kurengera ibidukikije, ikoranabuhanga mu kirere, amakuru ya elegitoroniki, ingufu n’izindi nzego, kandi yabaye ceramic yubatswe idasubirwaho ifite imikorere myiza mu nganda nyinshi. Noneho reka nkwereke!

Gucumura

Gucumura bidafite ingufu bifatwa nkuburyo butanga ikizere cyo gucumura SiC. Ukurikije uburyo butandukanye bwo gucumura, gucumura bidafite umuvuduko birashobora kugabanywamo ibice bikomeye byo gucumura no gucamo ibice. Binyuze muri ultra-nziza β- Umubare ukwiye wa B na C (ogisijeni iri munsi ya 2%) wongeyeho ifu ya SiC icyarimwe, na s. proehazka yashizwe mumubiri wa SiC yacumuye hamwe n'ubucucike buri hejuru ya 98% muri 2020 ℃. A. Mulla n'abandi. Al2O3 na Y2O3 byakoreshejwe nk'inyongeramusaruro kandi bigacumura kuri 1850-1950 ℃ kuri 0.5 μ m β- SiC (ubuso burimo ibice bike bya SiO2). Ubucucike bugereranije bwububiko bwa SiC bwabonetse burenze 95% byubucucike bwa theoretical, kandi ingano ni nto kandi nubunini buringaniye. Ni microni 1.5.

Gushyira ahagaragara

SiC irashobora gusa gucumurwa neza mubushyuhe bwo hejuru cyane nta kintu cyongeweho icyaha, kuburyo abantu benshi bashyira mubikorwa uburyo bwo gucumura bishyushye kuri SiC. Habayeho raporo nyinshi kuri sinteri ishyushye ya SiC wongeyeho infashanyo zo gucumura. Alliegro n'abandi. Yize ku ngaruka za boron, aluminium, nikel, icyuma, chromium nibindi byongeweho ibyuma kuri densification ya SiC. Ibisubizo byerekana ko aluminium nicyuma aribintu byongera imbaraga mugutezimbere SiC ishyushye. FFlange yize ku ngaruka zo kongeramo umubare utandukanye wa Al2O3 kumiterere ya SiC ishyushye. Bifatwa ko kwiyongera kwa SiC bishyushye bifitanye isano nuburyo bwo gusesa no kugwa. Ariko, uburyo bushyushye bwo gucumura bushobora kubyara ibice bya SiC gusa nuburyo bworoshye. Ubwinshi bwibicuruzwa byakozwe nigihe kimwe gishyushye cyo gucumura imashini ni nto cyane, ntabwo bifasha umusaruro winganda.

Gushyushya isostatike ikanda

Kugirango tuneshe ibitagenda neza muburyo bwo gucumura gakondo, ubwoko bwa B na C bwakoreshejwe nk'inyongeramusaruro kandi hifashishijwe ikoranabuhanga rishyushye rya isostatike. Kuri 1900 ° C, habonetse ububumbyi bwiza bwa kirisiti ifite ubucucike burenga 98, kandi imbaraga zo kugonda ubushyuhe bwicyumba zishobora kugera kuri MPa 600. Nubwo gususurutsa isostatike ishyushye bishobora kubyara ibicuruzwa byuzuye bifite imiterere igoye kandi ifite imashini nziza, gucumura bigomba gufungwa, bigoye kugera kumusaruro winganda.

Icyaha

Imyitwarire ya silicon karbide, izwi kandi kwizina rya silicon karbide yonyine, bivuga inzira ya bilet yifata hamwe na gaze cyangwa icyiciro cyamazi kugirango irusheho kunoza fagitire, kugabanya ubukana, hamwe nibicuruzwa byarangiye bifite imbaraga kandi byukuri. fata α- SiC ifu na grafite bivangwa mukigero runaka hanyuma bishyushye kugeza kuri 1650 ℃ kugirango ube fagitire kare. Muri icyo gihe, yinjira cyangwa yinjira muri bilet ikoresheje gaze ya Si kandi igakora hamwe na grafite kugirango ikore β- SiC, ihujwe nuduce duto twa α- SiC. Iyo Si yinjiye rwose, reaction yahinduye umubiri hamwe nubucucike bwuzuye hamwe nubunini butagabanuka burashobora kuboneka. Ugereranije nubundi buryo bwo gucumura, ingano yubunini bwa reaction yogucumura mubikorwa bya densification ni nto, kandi ibicuruzwa bifite ubunini nyabwo birashobora gutegurwa. Ariko, kubaho kwa SiC kwinshi mumubiri wacumuye bituma imiterere yubushyuhe bwo hejuru bwa reaction yahinduye ububumbyi bwa SiC.

Igihe cyo kohereza: Jun-08-2022