1. Brazeability

Umutungo wa brazing ya aluminium na aluminiyumu urakennye, cyane cyane ko firime ya okiside hejuru bigoye kuyikuramo. Aluminium ifitanye isano ya ogisijeni. Nibyoroshye gukora firime yuzuye, itajegajega kandi hejuru yo gushonga ya okiside ya firime Al2O3 hejuru. Muri icyo gihe, aluminiyumu ya aluminiyumu irimo magnesium nayo izakora firime ya oxyde ihamye cyane MgO. Bazabangamira cyane kugurisha no gukwirakwiza kugurisha. Kandi biragoye kuvanaho. Mugihe cyo gushakisha, inzira yo gushakisha irashobora gukorwa gusa hamwe na flux ikwiye.

Icya kabiri, imikorere ya aluminium na aluminium alloy brazing iragoye. Gushonga ingingo ya aluminium na aluminiyumu ntaho itandukaniye cyane nicyuma cyuzuza icyuma gikoreshwa. Ubushyuhe bwubushake bwo guhitamo ni buke cyane. Kugenzura ubushyuhe budakwiye biroroshye gutera ubushyuhe bwinshi cyangwa no gushonga ibyuma shingiro, bigatuma inzira yo gushakisha bigoye. Amavuta ya aluminiyumu akomezwa no kuvura ubushyuhe nabyo bizatera ibintu byoroshya nko gusaza cyangwa annealing bitewe no gushyushya umuriro, bizagabanya imiterere yingingo zasenyutse. Mugihe cyo gucana umuriro, biragoye kumenya ubushyuhe kuko ibara rya aluminiyumu ntirihinduka mugihe cyo gushyushya, ibyo bikaba byongera ibisabwa kurwego rwimikorere.

Byongeye kandi, kwangirika kwangirika kwa aluminium na aluminiyumu alloy ifatanye ingingo byangizwa byoroshye nibyuma byuzuza ibintu. Ubushobozi bwa electrode ya aluminium na aluminiyumu iratandukanye cyane niyagurishijwe, igabanya kurwanya ruswa yibihuru, cyane cyane kubigurisha byoroshye. Mubyongeyeho, ibyinshi mumazi akoreshwa mugukata aluminiyumu na aluminiyumu bifite ruswa ikomeye. Nubwo basukuye nyuma yo gushakisha, ingaruka za flux zirwanya kwangirika kwingingo ntizizakurwaho burundu.

2. Ibikoresho byo gushakisha

. Kugurisha byoroheje bifata cyane cyane kugurisha zinc no kugurisha amabati, bishobora kugabanywa kugurisha ubushyuhe buke (150 ~ 260 ℃), kugurisha ubushyuhe buciriritse (260 ~ 370 ℃) hamwe nugurisha ubushyuhe bwinshi (370 ~ 430 ℃) ukurikije ubushyuhe bwubushyuhe. Iyo amabati yagurishijwe akoreshwa hanyuma umuringa cyangwa nikel bigashyirwa mbere hejuru ya aluminiyumu kugirango bishashe, ruswa ishobora guhurizwa hamwe, kugirango irusheho kurwanya ruswa.

Gukata aluminiyumu na aluminiyumu ikoreshwa cyane, nka filteri, filteri, moteri hamwe nibindi bice. Gusa ibyuma bishingiye kuri aluminiyumu birashobora gukoreshwa mugukata aluminiyumu na aluminiyumu, muri byo harimo ibyuma bya aluminium silicon yuzuza cyane. Ingano yihariye yo gukoreshwa hamwe nimbaraga zo gukata zifatanije zerekanwe kumeza 8 nimbonerahamwe 9. Nyamara, aho gushonga k'uyu ugurisha yegereye icyuma fatizo, bityo ubushyuhe bwo gushyushya bugomba kugenzurwa neza kandi neza mugihe cyo gutwika kugirango wirinde gushyuha cyangwa gushonga ibyuma byibanze.

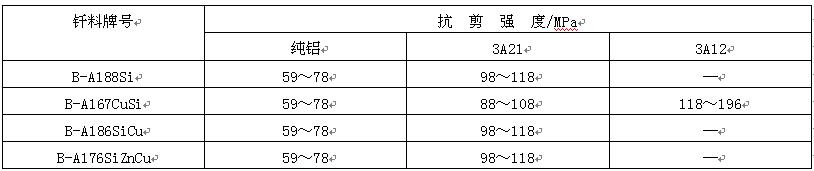

Imbonerahamwe 8 ikoreshwa murwego rwo gushakisha ibyuma byuzuza aluminium na aluminium

Imbonerahamwe 9 yogosha imbaraga za aluminium na aluminiyumu ivanze hamwe na aluminium silicon yuzuza ibyuma

Kugurisha aluminium silicon mubisanzwe itangwa muburyo bwa poro, paste, insinga cyangwa urupapuro. Rimwe na rimwe, uwagurishije amasahani hamwe na aluminiyumu nkibanze na aluminium silicon ugurisha nkuko kwambara bikoreshwa. Ubu bwoko bwo kugurisha isahani ikozwe muburyo bwa hydraulic kandi ikoreshwa kenshi mubice bigize brazing. Mugihe cyo gushakisha, icyuma cyuzuza icyuma hejuru yicyapa gishonga kigashonga kandi kigatemba munsi ya capillary na gravit kugirango yuzuze icyuho.

. Amazi kama ashingiye kuri triethanolamine, nka fs204, akoreshwa hamwe nubushyuhe buke bwo kugurisha. Ibyiza byuru rujya n'uruza ni uko rudafite ingaruka nke zo kwangirika ku cyuma fatizo, ariko ruzatanga gaze nyinshi, izagira ingaruka ku guhanagura no gutobora uwagurishije. Amazi meza ashingiye kuri zinc chloride, nka fs203 na fs220a, akoreshwa nubushyuhe bwo hagati hamwe nubushyuhe bwo hejuru bugurisha. Amazi adashobora kwangirika cyane, kandi ibisigazwa byayo bigomba kuvanwaho nyuma yo gushakisha.

Kugeza ubu, gusya kwa aluminium na aluminiyumu biracyiganjemo gukuraho flux firime. Amashanyarazi akoreshwa arimo chloride ishingiye kuri flux na fluor ishingiye kuri flux. Amazi ya Chloride afite ubushobozi bukomeye bwo gukuraho firime ya okiside hamwe n’amazi meza, ariko bifite ingaruka zikomeye zo kwangirika ku cyuma fatizo. Ibisigisigi byayo bigomba kuvaho burundu nyuma yo gushakisha. Fluoride ishingiye kuri flux ni ubwoko bushya bwa flux, bufite ingaruka nziza zo gukuraho firime kandi nta kwangirika kwicyuma. Nyamara, ifite aho ishonga cyane hamwe nubushyuhe buke bwumuriro, kandi irashobora gukoreshwa gusa nuwagurishije aluminium silicon.

Iyo ukoresheje aluminiyumu na aluminiyumu, vacuum, kutagira aho bibogamiye cyangwa inert ikoreshwa. Iyo gukoresha vacuum byakoreshejwe, impamyabumenyi ya vacuum muri rusange igera kuri gahunda ya 10-3pa. Iyo gaze ya azote cyangwa argon ikoreshwa mukurinda, ubuziranenge bwayo bugomba kuba hejuru cyane, naho ikime kigomba kuba munsi ya -40 ℃

3. Gukoresha tekinoroji

Gukata aluminiyumu na aluminiyumu bifite ibyangombwa byinshi byo gusukura ahakorerwa. Kugirango ubone ubuziranenge bwiza, irangi ryamavuta hamwe na firime ya okiside hejuru bigomba kuvaho mbere yo gushakisha. Kuraho ikizinga cyamavuta hejuru hamwe na Na2CO3 yumuti wamazi mubushyuhe bwa 60 ~ 70 ℃ kuri 5 ~ 10min, hanyuma ukarabe namazi meza; Filime yo hejuru ya okiside irashobora gukurwaho no gushiramo igisubizo cyamazi ya NaOH kubushyuhe bwa 20 ~ 40 ℃ kuri 2 ~ 4min, hanyuma ukakaraba namazi ashyushye; Nyuma yo gukuraho irangi ryamavuta na firime ya okiside hejuru, igihangano kizakoreshwa hamwe nigisubizo cyamazi ya HNO3 kumurabyo wa 2 ~ 5min, hanyuma ugasukurwa mumazi atemba hanyuma ukuma. Igicapo cyakoreshejwe nubu buryo ntigishobora gukorwaho cyangwa kwanduzwa nundi mwanda, kandi kizashyirwa hagati ya 6 ~ 8h. Nibyiza guhita uhita niba bishoboka.

Uburyo bwo gusya bwa aluminium na aluminiyumu burimo cyane cyane gucana umuriro, kugurisha ibyuma no gucana itanura. Ubu buryo muri rusange bukoresha flux mugukata, kandi bifite ibisabwa bikomeye kubushyuhe n'ubushyuhe. Mugihe cyo gucana umuriro no kugurisha ibyuma, irinde gushyushya flux biturutse kumasoko yubushyuhe kugirango wirinde ko ubushyuhe butananirwa. Kubera ko aluminiyumu ishobora gushonga mugurisha yoroshye irimo ibintu byinshi bya zinc, gushyushya bigomba guhagarara igihe urugingo rumaze gushingwa kugirango birinde kwangirika kwicyuma. Rimwe na rimwe, gushiramo aluminiyumu na aluminiyumu rimwe na rimwe ntibikoresha flux, ahubwo ikoresha uburyo bwa ultrasonic cyangwa scraping kugirango ikureho firime. Mugihe ukoresheje gusiba kugirango ukureho firime yo gushakisha, banza ushushe igihangano kugeza ku bushyuhe bwo hejuru, hanyuma usibe igice cyo gukata igice cyakazi ukoresheje impera yinkoni yagurishijwe (cyangwa igikoresho cyo gusiba). Mugihe cyo kumena firime ya oxyde, amaherezo yuwagurishije azashonga kandi atose ibyuma shingiro.

Uburyo bwa brazing bwa aluminium na aluminiyumu burimo cyane cyane gutwika flame, gucana itanura, gusya dip, gushiramo vacuum na gaz ikingiwe na gaz. Flame brazing ikoreshwa cyane mubikorwa bito no gukora igice kimwe. Kugirango wirinde kunanirwa kwa flux kubera guhuza umwanda uri muri acetylene na flux mugihe ukoresheje flame oxyacetylene, birakwiye ko ukoresha lisansi yugarijwe numuriro hamwe nigabanuka rito kugirango wirinde okiside yicyuma fatizo. Mugihe cyo gukonjesha, flux flux hamwe nicyuma cyuzuza birashobora gushyirwa ahantu hashyizwe hakiri kare hanyuma bigashyuha icyarimwe hamwe nakazi; Igicapo gishobora kandi gushyukwa mbere yubushyuhe bukabije, hanyuma uwagurishije akoresheje flux arashobora koherezwa kumwanya wa brazing; Nyuma yo gushiramo ibyuma no kuzuza, umuriro wo gushyushya ugomba gukurwaho buhoro nyuma yicyuma cyuzuye cyuzuye.

Iyo usya aluminiyumu na aluminiyumu mu itanura ry’ikirere, icyuma cyuzuza icyuma kizashyirwaho mbere, kandi flux yo gushonga igomba gushongeshwa mumazi yatoboye kugirango hategurwe igisubizo kibyibushye hamwe na 50% ~ 75%, hanyuma kigashyirwa hejuru cyangwa kigaterwa hejuru. Ingano ikwiye ya porojeri yamashanyarazi irashobora kandi gutwikirwa hejuru yicyuma cyuzuza no hejuru, hanyuma gusudira byateranijwe bigashyirwa mumatanura kugirango ushushe. Kugirango wirinde icyuma fatizo gushyuha cyangwa gushonga, ubushyuhe bwo gushyushya bugomba kugenzurwa cyane.

Ugurisha paste cyangwa file ikoreshwa mubisanzwe mugukoresha dip ya aluminium na aluminiyumu. Igicapo cyateranijwe kigomba gushyukwa mbere yo gukonjesha kugirango ubushyuhe bwacyo bugere ku bushyuhe bwo hejuru, hanyuma bigashyirwa mumazi yo gushakisha. Mugihe cyo gushakisha, ubushyuhe bwumwanya nigihe cyo gukonjesha bigomba kugenzurwa cyane. Niba ubushyuhe buri hejuru cyane, icyuma cyibanze kiroroshye gushonga kandi ugurisha byoroshye kubura; Niba ubushyuhe buri hasi cyane, uwagurishije ntashonga bihagije, kandi igipimo cyo kugabanuka kigabanuka. Ubushyuhe bwo gutwika bugomba kugenwa hakurikijwe ubwoko nubunini bwicyuma fatizo, ibigize hamwe nugushonga kwicyuma cyuzuza, kandi muri rusange kiri hagati yubushyuhe bwamazi bwicyuma cyuzuza nubushyuhe bukomeye bwicyuma fatizo. Igihe cyo kwibira cyakazi mu bwogero bwa flux kigomba kwemeza ko ugurisha ashobora gushonga neza kandi akagenda, kandi igihe cyo gushyigikira ntigikwiye kuba kirekire. Bitabaye ibyo, element ya silicon mubagurisha irashobora gukwirakwira mubyuma fatizo, bigatuma icyuma fatizo hafi yicyuma cyacitse.

Muri vacuum brazing ya aluminium na aluminiyumu, ibyuma bikoresha ibyuma bikoreshwa muguhindura firime ya oxyde yo hejuru ya aluminium no kwemeza ko kugurisha no gukwirakwiza. Manyeziyumu irashobora gukoreshwa mu buryo butaziguye ku gihangano cyakozwe mu buryo bwa buke, cyangwa ikinjizwa muri zone ya brazing mu buryo bwa parike, cyangwa magnesium irashobora kongerwa kubagurisha aluminium silicon nk'ikintu kivanze. Kubikorwa byakazi bifite imiterere igoye, kugirango hamenyekane ingaruka zuzuye ziva mumyuka ya magnesium kumyuma fatizo no kunoza ubwiza bwa brazing, ingamba zo gukingira zaho akenshi zifatwa, ni ukuvuga ko igihangano cyabanje gushyirwa mumasanduku yicyuma kitagira umwanda (bakunze kwita agasanduku k'ibikorwa), hanyuma ugashyirwa mu itanura rya vacuum kugirango ushushe. Vacuum Brazed Aluminium na aluminiyumu ivanze bifite ubuso bunoze hamwe nuduce twinshi twa braze, kandi ntibikeneye kozwa nyuma yo gusya; Nyamara, ibikoresho byo kumena vacuum bihenze, kandi imyuka ya magnesium ihumanya itanura cyane, bityo igomba guhanagurwa no kubungabungwa kenshi.

Iyo usize aluminiyumu na aluminiyumu mu kirere kitagira aho kibogamiye cyangwa inert, moteri ya magnesium cyangwa flux irashobora gukoreshwa mugukuraho firime. Iyo moteri ya magnesium ikoreshwa mugukuraho firime, ingano ya magnesium isabwa ni mike cyane ugereranije na vacuum brazing. Mubisanzwe, w (mg) ni 0.2% ~ 0.5%. Iyo ibirimo magnesium ari byinshi, ubwiza bwingingo buzagabanuka. Uburyo bwa brazing ya NOCOLOK ukoresheje fluor flux no kurinda azote nuburyo bushya bwateye imbere vuba mumyaka yashize. Kubera ko ibisigisigi bya fluoride bidakurura ubuhehere kandi ntibishobora kwangirika kuri aluminiyumu, inzira yo gukuraho ibisigazwa bya flux nyuma yo gushakisha irashobora kuvaho. Mu rwego rwo kurinda azote, hagomba gushyirwaho akantu gato ka fluoride, icyuma cyuzuza gishobora guhanagura neza ibyuma fatizo, kandi biroroshye kubona ingingo zujuje ubuziranenge. Kugeza ubu, ubu buryo bwo gushakisha NOCOLOK bwakoreshejwe mugukora cyane amashanyarazi ya aluminium nibindi bice.

Kuri aluminiyumu na aluminiyumu ivanze na flux usibye fluoride flux, ibisigara bya flux bigomba kuvaho burundu nyuma yo gushakisha. Ibisigisigi bya organic brazing flux ya aluminiyumu birashobora gukaraba hamwe nibisubizo kama nka methanol na trichlorethylene, bigahinduka hamwe na hydroxide hydroxide yumuti wamazi, hanyuma bigasukurwa namazi ashyushye nubukonje. Chloride nigisigara cya brazing flux ya aluminium, ishobora gukurwaho ukurikije uburyo bukurikira; Ubwa mbere, shira mumazi ashyushye kuri 60 ~ 80 ℃ kuminota 10, usukure neza ibisigara kumutwe wasizwe hamwe na brush, hanyuma ubisukure namazi akonje; Noneho shyira muri 15% acide ya acide ya acide ya 30min, hanyuma ubyoze n'amazi akonje.

Igihe cyo kohereza: Jun-13-2022