1. Brazeability

Biragoye gutwika ceramic na ceramic, ceramic nicyuma.Benshi mubagurisha bakora umupira hejuru yubutaka, hamwe no gutose.Icyuma cyuzuza ibyuma gishobora guhanagura ibumba ryoroshye biroroshye gukora ibintu bitandukanye bivanze (nka karbide, siliside na ternary cyangwa ibice byinshi) muburyo bumwe mugihe cyo gushakisha.Kubaho kwibi bikoresho bigira ingaruka kumiterere yingingo.Byongeye kandi, kubera itandukaniro rinini rya coefficient zo kwagura ubushyuhe hagati yubutaka, ibyuma ndetse nuwagurishije, hazabaho imihangayiko isigaye mu gihimba nyuma yubushyuhe bwo gukonjesha bukonje kugeza ubushyuhe bwicyumba, bushobora gutera gucikamo ibice.

Ubushuhe bwumugurisha hejuru yubutaka bwa ceramic burashobora kunozwa wongeyeho ibintu byuma bikora kubagurisha bisanzwe;Ubushyuhe buke nigihe gito cyo gushakisha birashobora kugabanya ingaruka za reaction reaction;Imyuka yubushyuhe yingingo irashobora kugabanuka mugushushanya uburyo bukwiye hamwe no gukoresha icyuma kimwe cyangwa ibyiciro byinshi nkurwego rwagati.

2. Umucuruzi

Ceramic nicyuma mubisanzwe bihuzwa mumatanura ya vacuum cyangwa hydrogen hamwe nitanura rya argon.Usibye ibiranga rusange, gushakisha ibyuma byuzuza ibikoresho bya elegitoroniki bigomba no kugira bimwe byihariye bisabwa.Kurugero, umugurisha ntagomba kubamo ibintu bitanga umuvuduko mwinshi wumuyaga, kugirango bidatera kumeneka dielectric hamwe nuburozi bwa cathode yibikoresho.Muri rusange biragaragara ko mugihe igikoresho gikora, umuvuduko wumwuka wumugurisha ntushobora kurenga 10-3pa, kandi umwanda mwinshi wumuyaga urimo ntushobora kurenga 0.002% ~ 0.005%;W.Byongeye kandi, ugurisha agomba kuba afite isuku kandi nta oxyde yo hejuru.

Iyo gukarabirana nyuma yubutaka bwa ceramic, umuringa, shingiro, umuringa wa feza, umuringa wa zahabu nibindi byuma byuzuza ibyuma bishobora gukoreshwa.

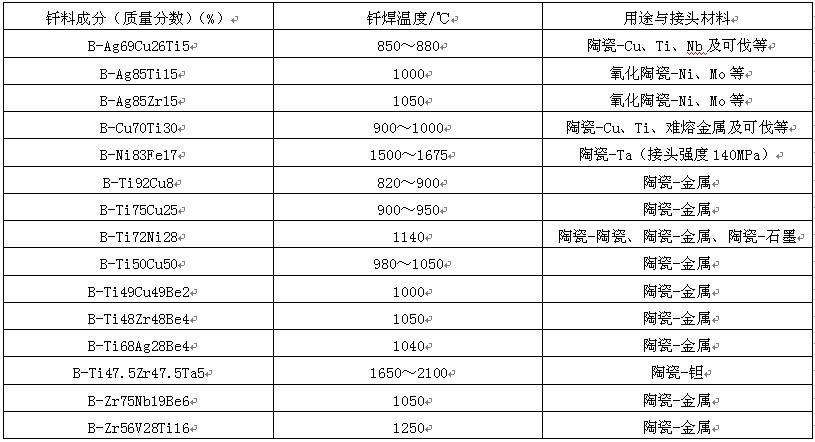

Kubijyanye no gutondeka neza kubumba nubutare, hazatorwa ibyuma byuzuza ibintu birimo ibintu bikora Ti na Zr.Ibyuma byuzuza ibyuma ni Ti Cu na Ti Ni, bishobora gukoreshwa kuri 1100 ℃.Mu bagurisha ternary, Ag Cu Ti (W) (TI) nimwe mu bicuruzwa bikoreshwa cyane, bishobora gukoreshwa mu gutondagura mu buryo butaziguye ububumbyi butandukanye n’ibyuma.Icyuma cyuzuza ternary gishobora gukoreshwa na file, ifu cyangwa Ag Cu eutectic yuzuza ibyuma hamwe na Ti powder.B-ti49be2 icyuma cyuzuza ibyuma bifite ruswa irwanya ruswa idashobora kwangirika hamwe numuvuduko muke wumuyaga.Irashobora guhitamo muburyo bwo gufunga vacuum hamwe na okiside hamwe no kurwanya imyanda.Mugurisha ti-v-cr, ubushyuhe bwo gushonga nubushyuhe buke (1620 ℃) mugihe w (V) ari 30%, kandi kongeramo Cr birashobora kugabanya neza ubushyuhe bwubushyuhe.B-ti47.5ta5 ugurisha nta Cr yakoreshejwe mugukata mu buryo butaziguye alumina na oxyde ya magnesium, kandi ingingo yayo irashobora gukora ku bushyuhe bw’ibidukikije bwa 1000 ℃.Imbonerahamwe 14 yerekana flux ikora ihuza itaziguye hagati yubutaka nicyuma.

Imbonerahamwe 14 ikora brazing yuzuza ibyuma bya ceramic nicyuma

2. Gukoresha tekinoroji

Ububiko bwambere bwabugenewe bushobora gutondekwa muri gaze ya inert yuzuye, hydrogène cyangwa ibidukikije.Gukoresha Vacuum muri rusange bikoreshwa mugukata neza kubutaka butarimo metallisation.

.

Intego yo gusukura hejuru ni ugukuraho amavuta, ibyuya byu icyuya na firime ya okiside hejuru yicyuma.Ibice byicyuma nugurisha bigomba kubanza guteshwa agaciro, hanyuma firime ya oxyde ikurwaho na acide cyangwa gukaraba alkali, gukaraba n'amazi atemba hanyuma akuma.Ibice bifite ibyangombwa byinshi bigomba gutunganywa ubushyuhe mu itanura rya vacuum cyangwa itanura rya hydrogène (uburyo bwa ion bombardment na bwo burashobora gukoreshwa) mubushyuhe bukwiye nigihe cyo kweza ubuso bwibice.Ibice bisukuye ntibishobora guhura nibintu byamavuta cyangwa amaboko yambaye ubusa.Bizahita bishyirwa mubikorwa bikurikiraho cyangwa byumye.Ntibashobora guhumeka ikirere igihe kirekire.Ibice bya ceramic bigomba guhanagurwa na acetone na ultrasonic, bigakaraba n'amazi atemba, hanyuma bigatekwa kabiri n'amazi ya deionioni 15min buri mwanya

Kwambika ibara ni inzira yingenzi yo gutondekanya ceramic.Mugihe cyo gutwikira, bikoreshwa hejuru yubutaka kugirango bicuzwe hamwe na mashine yohasi.Ubunini bwa coating muri rusange ni 30 ~ 60mm.Ubusanzwe paste itegurwa uhereye kumafu yicyuma (rimwe na rimwe hiyongeraho okiside yicyuma) hamwe nubunini bugera kuri 1 ~ 5um hamwe na organic organique.

Ibice bya ceramique byometse byoherezwa mu itanura rya hydrogène hanyuma bigashyirwa hamwe na hydrogène itose cyangwa ammonia yacitse kuri 1300 ~ 1500 ℃ kuri 30 ~ 60min.Kubice bya ceramic bisizwe na hydride, bizashyuha kugeza kuri 900 ℃ kugirango bibore hydride hanyuma bigakorwa nicyuma cyiza cyangwa titanium (cyangwa zirconium) gisigaye hejuru yubutaka kugirango babone icyuma hejuru yubutaka.

Kuri Mo Mn metallized layer, kugirango itume itose hamwe nuwagurishije, nikel ya 1.4 ~ 5um igomba guhindurwa amashanyarazi cyangwa igashyirwaho igipande cyifu ya nikel.Niba ubushyuhe bukabije buri munsi ya 1000 ℃, nikel igomba kubanza gucumurwa mu itanura rya hydrogen.Ubushyuhe bwo gucumura nigihe ni 1000 ℃ / 15 ~ 20min.

Ubukorikori buvuwe ni ibice byicyuma, bizateranirizwa hamwe hamwe nicyuma kitagira umwanda cyangwa grafite na ceramic.Solder igomba gushyirwa hamwe, kandi igihangano kigomba guhorana isuku mugikorwa cyose, kandi ntigikoraho amaboko yambaye ubusa.

Brazing igomba gukorwa muri argon, hydrogen cyangwa itanura rya vacuum.Ubushyuhe bwa brazing buterwa nicyuma cyuzuza.Kugirango wirinde gucikamo ibice byubutaka, igipimo cyo gukonjesha ntigishobora kwihuta cyane.Mubyongeyeho, gushakisha bishobora no gukoresha igitutu runaka (hafi 0.49 ~ 0.98mpa).

Usibye ubugenzuzi bwubuziranenge bwubuso, gusudira gusya bigomba no guhura nubushyuhe bwumuriro no kugenzura imitungo.Ibice bifunga ibikoresho bya vacuum bigomba kandi gukorerwa ibizamini bisohoka ukurikije amabwiriza abigenga.

.Kugirango wirinde ibice byatewe na coefficient zitandukanye zo kwagura ubushyuhe bwibikoresho bigize ibice, urwego rwa buffer (igice kimwe cyangwa byinshi byamabati) birashobora kuzunguruka hagati yo gusudira.Icyuma cyuzuza icyuma kigomba gufatanwa hagati yo gusudira cyangwa gushyirwa kumwanya aho icyuho cyuzuyemo icyuma cyuzuza ibyuma bishoboka, hanyuma guswera bigakorwa nkibisanzwe bisanzwe.

Niba Ag Cu Ti ugurisha akoreshwa muburyo butaziguye, hazakoreshwa uburyo bwo gushakisha vacuum.Iyo impamyabumenyi ya vacuum mu itanura igeze kuri 2.7 × Tangira gushyushya 10-3pa, kandi ubushyuhe burashobora kuzamuka vuba muri iki gihe;Iyo ubushyuhe buri hafi yo gushonga k'umugurisha, ubushyuhe bugomba kuzamurwa buhoro kugirango ubushyuhe bwibice byose byo gusudira bikunda kuba bimwe;Iyo umugurisha ashonge, ubushyuhe buzamurwa vuba kugeza ubushyuhe bukabije, kandi igihe cyo gufata kizaba 3 ~ 5min;Mugihe cyo gukonjesha, igomba gukonjeshwa buhoro mbere ya 700 ℃, kandi irashobora gukonjeshwa bisanzwe hamwe nitanura nyuma ya 700 ℃.

Iyo Ti Cu igurisha ikora neza, uburyo bwo kugurisha bushobora kuba Cu foil wongeyeho ifu ya Ti cyangwa Cu ibice wongeyeho Ti foil, cyangwa ubuso bwa ceramic bushobora gushyirwaho ifu ya Ti wongeyeho Cu foil.Mbere yo gushakisha, ibice byose byicyuma bigomba guteshwa agaciro na vacuum.Ubushyuhe bwangirika bwumuringa wubusa wa ogisijeni bugomba kuba 750 ~ 800 and, naho Ti, Nb, Ta, nibindi bizamanurwa kuri 900 ℃ kuri 15min.Muri iki gihe, impamyabumenyi ya vacuum ntishobora kuba munsi ya 6.7 × 10-3Pa。 Mugihe cyo gushakisha, guteranya ibice bigomba gusudira mu bikoresho, ubishyushya mu ziko rya vacuum kugeza 900 ~ 1120 and, kandi igihe cyo gufata ni 2 ~ 5min.Mugihe cyose cyo gushakisha, impamyabumenyi ya vacuum ntishobora kuba munsi ya 6.7 × 10-3Pa。

Uburyo bwo gushakisha uburyo bwa Ti Ni busa nuburyo bwa Ti Cu, kandi ubushyuhe bwa brazing ni 900 ± 10 ℃.

.Irashobora guhuza ububumbyi nubutaka nubutaka hamwe nicyuma.Oxide brazing yuzuza ibyuma bigizwe ahanini na Al2O3, Cao, Bao na MgO.Wongeyeho B2O3, Y2O3 na ta2o3, ushobora kubona ibyuma byuzuza ibyuma bitandukanye byo gushonga hamwe na coefficient yo kwagura umurongo.Byongeye kandi, fluor brazing yuzuza ibyuma hamwe na CaF2 na NaF nkibice byingenzi birashobora kandi gukoreshwa muguhuza ububumbyi nubutare kugirango ubone ingingo zifite imbaraga nyinshi kandi zirwanya ubushyuhe bwinshi.

Igihe cyo kohereza: Jun-13-2022